- Αρχική

- Εταιρεία

-

Μηχανήματα

-

Mutoh

- Εκτυπωτικά Ψηφιακής Εκτύπωσης & Επιγραφοποιίας

- Εκτυπωτικά Dye Sublimation & Digital Transfer

- Εκτυπωτικά Direct Textile

-

Specialty / Industrial UV Printers

-

Mutoh *All uv models

Mutoh *All uv models

-

ValueJet 426UF

ValueJet 426UF

-

XpertJet XPJ-461UF (model 2020)

XpertJet XPJ-461UF (model 2020)

-

XpertJet 461uf (video)

XpertJet 461uf (video)

-

XpertJet 461uf (Product Demonstration)

XpertJet 461uf (Product Demonstration)

-

ValueJet 626UF (video)

ValueJet 626UF (video)

-

XpertJet XPJ-661UF ( model 2020)

XpertJet XPJ-661UF ( model 2020)

-

XpertJet 661UF (video)

XpertJet 661UF (video)

-

XpertJet 626/661 (Rotary System) *Σύστημα εκτύπωσης σε κυλινδρικά αντικείμενα.

XpertJet 626/661 (Rotary System) *Σύστημα εκτύπωσης σε κυλινδρικά αντικείμενα.

-

ValueJet 1626UH

ValueJet 1626UH

-

*new ValueJet 1638UR Mark II (Brochure pdf)

*new ValueJet 1638UR Mark II (Brochure pdf)

-

*new ValueJet 1638UR Mark II (Αναλυτική παρουσίαση pdf)

*new ValueJet 1638UR Mark II (Αναλυτική παρουσίαση pdf)

-

*new ValueJet 1638UR Mark II -Video

*new ValueJet 1638UR Mark II -Video

-

ValueJet 2508UF

ValueJet 2508UF

-

ValueJet 2508UF (video)

ValueJet 2508UF (video)

-

ValueJet 2508UF (video #2)

ValueJet 2508UF (video #2)

-

- Options & Inks

- Technology

- Smart Color Hybrid printers (Mutoh)

-

Flora

- Solvent Printers

- Uv Flatbed Printersμε ιμάντα προώθησης (F1)

-

Uv Flatbed Printersμε σταθερό τραπέζι (PP)

- PP - 1612UV/Ricoh1,60m x 1,22m/Ricoh Gen5

- PP - 1816UV3,20m x 1,8m/Konica Minolta512

- PP - 2512UV2,50m x 1,22m/Konica Minolta 512

- PP - 2512UV/Turbo2,50m x 1,22m/Konica Minolta1024

- PP - 2512UV/Eos2,50m x 1,22m/Toshiba CE4

- PP - 2512UV/Ricoh2,50m x 1,22m/Ricoh Gen5

- PP - 3218UV

- PP - 3220UV/Turbo3,20m x 2,0m/Konica Minolta1024

- PP - 3220UV Turbo/G

- XTRA3220_2512UV_EN

- Uv Roll to Roll Printers

- Industrial, Sublimation & Textile Printers

-

VenusLF

-

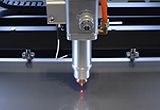

Laser Systems

- VenusLF - General

- VenusLF Lasers - Συλλογή Video

- VenusLF Lasers -Fiber για χάραξη σε μέταλλο

- VenusLF CMA13090

- VenusLF CMA13090 B/A (presentation pdf)

- VenusLF CMA13090 K/A (presentation pdf)

- VenusLF CMA13090 B/A (video)

- VenusLF CMA13090 K/A (video)

- VenusLF CMA4030 /pdf

- VenusLF CMA4030 video

- VenusLF VDL-0503 (pdf)

- VenusLF VDL-0503 (video)

- Led Uv Printers

- Eco Solvent Printers

- Textile Printers

- Πλαστικοποιητές

- Πρέσσες θερμομεταφορας 7/2021 (new)

- Πρέσσες θερμομεταφορας μεγάλου μεγέθους

- Digital Transfer to Film (60cm DTF)

- Digital Transfer to Film (30cm DTF)

-

Laser Systems

- Summa

-

GCC

- DTG Textile & T-shirt Printers

- Sei industrial Laser systems

- AXYZ

- Aristo

- Neolt

- Συστήματα UPS

- Μεταχειρισμένα Μηχανήματα

- Μεταχειρισμένα Μηχανήματα-Ενημέρωση 7/12/2020

-

Mutoh

- Marketing

-

Videos

- Video - Παρουσίαση demo room.

- Video από Graphica 2019

- Video από Graphica 2017

- Videos (Διάφορα)

- Videos (Γενική παρουσίαση των μηχανημάτων της Mutoh)

- Videos (Mutoh Led Uv 2508 250cm x 125cm)

- Virtual Tour 360 (Εικονική περιήγηση στο show room της Mutoh στο Βέλγιο)

- Videos (Mutoh Channel)

- 9 Mutoh videos for XpertJet 461UF/661UF (technical/training videos)

- Mutoh XpertJet Led Uv 461/661 uf (Series presentation)

- XpertJet led uv 461/661uf (Product Demonstration)

- Videos (Mutoh guide)

- Videos Laser VenusLF (Video από διάφορες κοπές)

- Videos Laser VenusLF (compare 130w vs 200w)

- Support

- Επικοινωνία

- e-shop(B2B)

- [Mετάβαση στο νέο μας site www.dataworks-automation.gr !!]

- [Mετάβαση στο νέο μας site www.dataworks-automation.gr !!] ..

- [Mετάβαση στο νέο μας site www.dataworks-automation.gr !!] ...

- [Mετάβαση στο νέο μας site www.dataworks-automation.gr !!] ....

|

|

♦ ValueJet 426UF

- Desktop A3+ Flatbed LED UV Printer

|

Desciption

The GCC LaserPro MG380Hybrid is equipped with metal laser tube and glass laser tube at the same time which allow user to produce superior engraving and cutting work piece. All in one machine save your storage space and make your profit maximum. The GCC LaserPro users always have an edge over the others with numerous uniquely innovative and user friendly features.

Feature

Optional Items

Specifications

*Speed is not equal to throughput.

Company's Website

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice.

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice.

*Speed is not equal throughput. See dealer or visit http://www.gccworld.com for more details. Two In-line ‘Wide Model’ Heads The ValueJet 2628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour. The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds. Performance The VJ-2628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print Technology The ValueJet 2628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles. One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print Platform A unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media Handling Several features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Mutoh Disperse Dye Sublimation & Direct Disperse Inks are 100 % VOC free and do not contain any hazardous components. These water-based inks have excellent nozzle stability for high speed and high volume printing. They offer a large colour gamut for rich and vibrant colours and deliver top scores in light fastness, wash fastness, rubbing and perspiration.

Mutoh dye sublimation inks deliver perfect transfer to different materials (textiles and rigids). The direct disperse inks are suited for direct printing onto polyester fabrics. Ink Set-up Possibilities The ValueJet 2628TD printer– with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

Brochures Specification Sheet Read Also Two In-line ‘Wide Model’ Heads The ValueJet 1628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour. The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds. Performance The VJ-1628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print Technology The ValueJet 1628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles. One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print Platform A unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media Handling Several features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Mutoh Disperse Dye Sublimation & Direct Disperse Inks are 100 % VOC free and do not contain any hazardous components. These water-based inks have excellent nozzle stability for high speed and high volume printing. They offer a large colour gamut for rich and vibrant colours and deliver top scores in light fastness, wash fastness, rubbing and perspiration. Mutoh dye sublimation inks deliver perfect transfer to different materials (textiles and rigids). The direct disperse inks are suited for direct printing onto polyester fabrics. Ink Set-up Possibilities The ValueJet 1628TD printer - with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

|

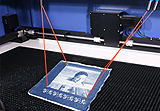

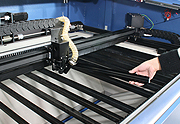

Laser Cutting Range

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Description

Embrace the cutting technology from the GCC LaserPro X series designed and engineered for professional use. Packed with several user-friendly features, the GCC LaserPro X500III offers high product performance in terms of both durability and feasibility. The X500III model combines cutting and engraving capabilities to give users a versatile system. Features

Optional Items

Specifications

*Speed is not equal to throughput. See dealer or visit www.GCCworld.com for more details.

Company's Website

*Speed does not equal to throughput. See dealer or visit www.gccworld.com for more details.

*Speed is not equal throughput. See dealer or visit http://www.gccworld.com for more details. Two In-line ‘Wide Model’ Heads The ValueJet 2628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour. The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds. Performance The VJ-2628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print Technology The ValueJet 2628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles. One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print Platform A unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media Handling Several features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Mutoh Disperse Dye Sublimation & Direct Disperse Inks are 100 % VOC free and do not contain any hazardous components. These water-based inks have excellent nozzle stability for high speed and high volume printing. They offer a large colour gamut for rich and vibrant colours and deliver top scores in light fastness, wash fastness, rubbing and perspiration.

Mutoh dye sublimation inks deliver perfect transfer to different materials (textiles and rigids). The direct disperse inks are suited for direct printing onto polyester fabrics. Ink Set-up Possibilities The ValueJet 2628TD printer– with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

Brochures Specification Sheet Read Also Two In-line ‘Wide Model’ Heads The ValueJet 1628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour. The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds. Performance The VJ-1628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print Technology The ValueJet 1628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles. One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print Platform A unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media Handling Several features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Mutoh Disperse Dye Sublimation & Direct Disperse Inks are 100 % VOC free and do not contain any hazardous components. These water-based inks have excellent nozzle stability for high speed and high volume printing. They offer a large colour gamut for rich and vibrant colours and deliver top scores in light fastness, wash fastness, rubbing and perspiration. Mutoh dye sublimation inks deliver perfect transfer to different materials (textiles and rigids). The direct disperse inks are suited for direct printing onto polyester fabrics. Ink Set-up Possibilities The ValueJet 1628TD printer - with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

|

Laser Cutting Range

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

*Speed is not equal throughput. See dealer or visit http://www.gccworld.com for more details.

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice. Specification SheetOnline Video

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice.

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice. Two In-line ‘Wide Model’ Heads The ValueJet 2628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour.The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds.

PerformanceThe VJ-2628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print TechnologyThe ValueJet 2628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles.One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print PlatformA unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media HandlingSeveral features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Mutoh Disperse Dye Sublimation & Direct Disperse Inks are 100 % VOC free and do not contain any hazardous components. These water-based inks have excellent nozzle stability for high speed and high volume printing. They offer a large colour gamut for rich and vibrant colours and deliver top scores in light fastness, wash fastness, rubbing and perspiration.

Mutoh dye sublimation inks deliver perfect transfer to different materials (textiles and rigids). The direct disperse inks are suited for direct printing onto polyester fabrics.Ink Set-up PossibilitiesThe ValueJet 2628TD printer– with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

Brochures

Specification Sheet

Two In-line ‘Wide Model’ HeadsThe ValueJet 1628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour.The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds.

PerformanceThe VJ-1628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print TechnologyThe ValueJet 1628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles.One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print PlatformA unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media HandlingSeveral features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Ink Set-up PossibilitiesThe ValueJet 1628TD printer - with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice.

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice. Two In-line ‘Wide Model’ Heads The ValueJet 2628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour.The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds.

PerformanceThe VJ-2628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print TechnologyThe ValueJet 2628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles.One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print PlatformA unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media HandlingSeveral features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Mutoh Disperse Dye Sublimation & Direct Disperse Inks are 100 % VOC free and do not contain any hazardous components. These water-based inks have excellent nozzle stability for high speed and high volume printing. They offer a large colour gamut for rich and vibrant colours and deliver top scores in light fastness, wash fastness, rubbing and perspiration.

Mutoh dye sublimation inks deliver perfect transfer to different materials (textiles and rigids). The direct disperse inks are suited for direct printing onto polyester fabrics.Ink Set-up PossibilitiesThe ValueJet 2628TD printer– with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

Brochures

Specification Sheet

Two In-line ‘Wide Model’ HeadsThe ValueJet 1628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour.The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds.

PerformanceThe VJ-1628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print TechnologyThe ValueJet 1628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles.One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print PlatformA unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media HandlingSeveral features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Ink Set-up PossibilitiesThe ValueJet 1628TD printer - with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice. Two In-line ‘Wide Model’ Heads The ValueJet 2628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour.The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds.

PerformanceThe VJ-2628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print TechnologyThe ValueJet 2628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles.One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print PlatformA unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media HandlingSeveral features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Mutoh Disperse Dye Sublimation & Direct Disperse Inks are 100 % VOC free and do not contain any hazardous components. These water-based inks have excellent nozzle stability for high speed and high volume printing. They offer a large colour gamut for rich and vibrant colours and deliver top scores in light fastness, wash fastness, rubbing and perspiration.

Mutoh dye sublimation inks deliver perfect transfer to different materials (textiles and rigids). The direct disperse inks are suited for direct printing onto polyester fabrics.Ink Set-up PossibilitiesThe ValueJet 2628TD printer– with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

Brochures

Specification Sheet

Two In-line ‘Wide Model’ HeadsThe ValueJet 1628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour.The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds.

PerformanceThe VJ-1628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print TechnologyThe ValueJet 1628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles.One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print PlatformA unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media HandlingSeveral features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Ink Set-up PossibilitiesThe ValueJet 1628TD printer - with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

Specification

** File transmission at USB 2.0 Full Speed rate

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Description

The GCC LaserPro MG380Hybrid is equipped with metal laser tube and glass laser tube at the same time which allow user to produce superior engraving and cutting work piece. All in one machine save your storage space and make your profit maximum. The GCC LaserPro users always have an edge over the others with numerous uniquely innovative and user friendly features.

Feature

Optional Item

Specifications

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice.

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice. Specification SheetOnline Video

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice.

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice. Two In-line ‘Wide Model’ Heads The ValueJet 2628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour.The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds.

PerformanceThe VJ-2628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print TechnologyThe ValueJet 2628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles.One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print PlatformA unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media HandlingSeveral features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Mutoh Disperse Dye Sublimation & Direct Disperse Inks are 100 % VOC free and do not contain any hazardous components. These water-based inks have excellent nozzle stability for high speed and high volume printing. They offer a large colour gamut for rich and vibrant colours and deliver top scores in light fastness, wash fastness, rubbing and perspiration.

Mutoh dye sublimation inks deliver perfect transfer to different materials (textiles and rigids). The direct disperse inks are suited for direct printing onto polyester fabrics.Ink Set-up PossibilitiesThe ValueJet 2628TD printer– with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

Brochures

Specification Sheet

Two In-line ‘Wide Model’ HeadsThe ValueJet 1628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour.The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds.

PerformanceThe VJ-1628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print TechnologyThe ValueJet 1628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles.One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print PlatformA unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media HandlingSeveral features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Ink Set-up PossibilitiesThe ValueJet 1628TD printer - with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice.

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice. Two In-line ‘Wide Model’ Heads The ValueJet 2628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour.The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds.

PerformanceThe VJ-2628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print TechnologyThe ValueJet 2628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles.One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print PlatformA unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media HandlingSeveral features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Mutoh Disperse Dye Sublimation & Direct Disperse Inks are 100 % VOC free and do not contain any hazardous components. These water-based inks have excellent nozzle stability for high speed and high volume printing. They offer a large colour gamut for rich and vibrant colours and deliver top scores in light fastness, wash fastness, rubbing and perspiration.

Mutoh dye sublimation inks deliver perfect transfer to different materials (textiles and rigids). The direct disperse inks are suited for direct printing onto polyester fabrics.Ink Set-up PossibilitiesThe ValueJet 2628TD printer– with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

Brochures

Specification Sheet

Two In-line ‘Wide Model’ HeadsThe ValueJet 1628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour.The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds.

PerformanceThe VJ-1628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print TechnologyThe ValueJet 1628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles.One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print PlatformA unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media HandlingSeveral features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Ink Set-up PossibilitiesThe ValueJet 1628TD printer - with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice. Two In-line ‘Wide Model’ Heads The ValueJet 2628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour.The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds.

PerformanceThe VJ-2628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print TechnologyThe ValueJet 2628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles.One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print PlatformA unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media HandlingSeveral features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Mutoh Disperse Dye Sublimation & Direct Disperse Inks are 100 % VOC free and do not contain any hazardous components. These water-based inks have excellent nozzle stability for high speed and high volume printing. They offer a large colour gamut for rich and vibrant colours and deliver top scores in light fastness, wash fastness, rubbing and perspiration.

Mutoh dye sublimation inks deliver perfect transfer to different materials (textiles and rigids). The direct disperse inks are suited for direct printing onto polyester fabrics.Ink Set-up PossibilitiesThe ValueJet 2628TD printer– with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

Brochures

Specification Sheet

Two In-line ‘Wide Model’ HeadsThe ValueJet 1628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour.The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds.

PerformanceThe VJ-1628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print TechnologyThe ValueJet 1628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles.One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print PlatformA unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media HandlingSeveral features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Ink Set-up PossibilitiesThe ValueJet 1628TD printer - with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Description

Description

Features

Specifications

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice. Company Website

** File transmission at USB 2.0 Full Speed rate Specifications are subject to change without prior notice.

*Speed is not equal throughput. See dealer or visit http://www.gccworld.com for more details. Two In-line ‘Wide Model’ Heads The ValueJet 2628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour. The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds. Performance The VJ-2628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print Technology The ValueJet 2628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles. One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print Platform A unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media Handling Several features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Mutoh Disperse Dye Sublimation & Direct Disperse Inks are 100 % VOC free and do not contain any hazardous components. These water-based inks have excellent nozzle stability for high speed and high volume printing. They offer a large colour gamut for rich and vibrant colours and deliver top scores in light fastness, wash fastness, rubbing and perspiration.

Mutoh dye sublimation inks deliver perfect transfer to different materials (textiles and rigids). The direct disperse inks are suited for direct printing onto polyester fabrics. Ink Set-up Possibilities The ValueJet 2628TD printer– with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

Brochures Specification Sheet Read Also Two In-line ‘Wide Model’ Heads The ValueJet 1628TD textile printer incorporates two in-line latest generation piezo drop-on-demand variable drop “wide model” print heads. Each 1440-nozzle head (8 lines of 180 nozzles) incorporates four colour sections, each divided in two nozzle rows with 360 nozzles per colour. The print heads are capable of producing ink drops ranging from 5.5 pl to 34.5 pl. Bottom line, they can produce a wider range of ink dots, which are moreover jetted at a much faster speed compared to other print heads on the market. The result is faster output speeds and moreover a much better print quality at higher output speeds. Performance The VJ-1628TD printer offers you a wide range of print modes and speeds. The overview below lists the most popular ones with which impeccable printing quality can be obtained.

Maximize your Profit with Mutoh Intelligent Interweaving (i²) Print Technology The ValueJet 1628TD incorporates Mutoh’s award-winning Intelligent Interweaving (i²) print technology, enabling a drastic reduction or even total elimination of the typical difficulties inherent to conventional digital inkjet printing, such as horizontal banding, step mismatch banding and the visible effects of missing or misfiring nozzles. One of the biggest benefits of this proprietary Mutoh print technology is that it offers predictable and repeatable output quality, therefore bringing an unprecedented level of user comfort to the printer operator. ValueJet printer users will be able to print ideal quality images fit for purpose every time, in the shortest possible time. Adaptable Print Platform A unique feature of the Mutoh ValueJet TD printer is that it incorporates a new adaptable print platform, enabling both direct-to-fabric and dye sublimation (transfer paper) printing in one machine.

Worry-free Media Handling Several features have been integrated in the ValueJet TD printer to enable smooth and worry-free media handling for both direct-to-fabric and dye sublimation (transfer paper) printing.

Mutoh Disperse Dye Sublimation & Direct Disperse Inks are 100 % VOC free and do not contain any hazardous components. These water-based inks have excellent nozzle stability for high speed and high volume printing. They offer a large colour gamut for rich and vibrant colours and deliver top scores in light fastness, wash fastness, rubbing and perspiration. Mutoh dye sublimation inks deliver perfect transfer to different materials (textiles and rigids). The direct disperse inks are suited for direct printing onto polyester fabrics. Ink Set-up Possibilities The ValueJet 1628TD printer - with 8 ink channels / 8 cassette slots - offers full freedom of ink set up:

Applications:

|

Laser Cutting Range

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||